Slack Adjuster Lubricating

Important: Perform Parking Brake Operational Check before lubricating the slack adjusters.

Automatic slack adjusters that have a grease fitting, must be lubricated periodically to ensure proper brake operation.

Warning: Failure to lubricate slack adjusters could lead to dragging brakes or a brake failure, resulting in property damage, personal injury, or death.

Haldex

Notice: Do not use moly-disulfide-loaded grease or oil. Both the life and reliability of the slack adjuster will be reduced if this type of grease is used.

Lubricate the automatic slack adjuster at the grease fitting. See Fig.. Use standard chassis lubricant for Haldex slack adjusters.

Gunite

For operating temperatures of –20°F (–29°C) and higher, use Texaco Multifak EP-2 or Mobil Grease No. 77.

For operating temperatures between –20°F (–29°C) and –40°F (–40°C), use Lubriplate Aero grease.

Gunite automatic slack adjusters are produced without a grease relief. During lubrication with a grease gun, lubricant is forced through the drilled worm wheel onto the camshaft. Lubricate the automatic slack adjuster at the grease fitting until grease appears on the camshaft.

Meritor

Note: If equipped with an extended maintenance Q Plus™ brake system, the slack adjuster will not have a grease fitting. These slack adjusters use a special NLGI Grade synthetic polyurea grease and do not require lubrication for 3 years or 500,000 miles (800 000 km), whichever comes first. Extended maintenance slack adjusters should be lubricated during brake reline service. For service and lubrication instructions, see of the S2 Chassis Workshop Manual .

For slack adjusters with grease fittings and for operating temperatures above –40°F (–40°C), use an NLGI Grade 1 clay-base grease or an NLGI Grade 1 and 2 lithium-base grease.

For slack adjusters with grease fittings, and for operating temperatures below –40°F (–40°C) and above –65°F (–54°C), use a NLGI Grade 2 synthetic oil or a clay-base grease.

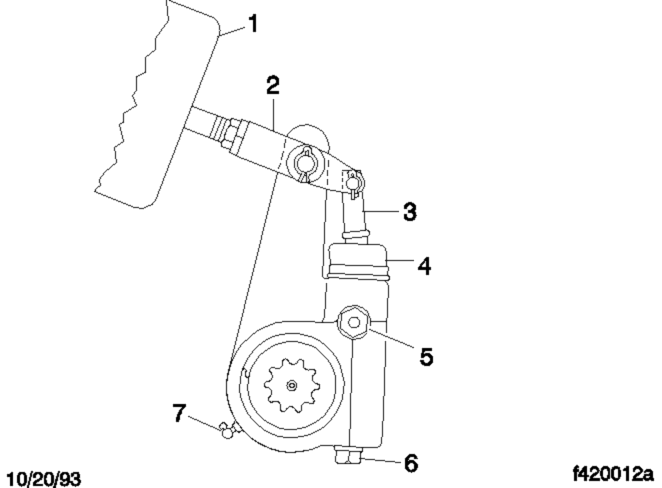

Lubricate the slack adjuster at the grease fitting until grease is forced past the pressure-relief capscrew or past the gear splines around the inboard snap ring. See Fig..

-

Brake Chamber

-

Clevis

-

Actuator Rod

-

Boot

-

Pull-Pawl Seal

-

Manual Adjusting Nut

-

Grease Fitting (or plug)

Fig. 2, Meritor Automatic Slack Adjuster

Bendix

Using a quality multipurpose chassis lubricant, NLGI Grade 2, lubricate the automatic slack adjuster through the lube fitting. See Fig.. Lubricate the slack adjuster until clean lubricant flows from the grease relief opening in the boot.