Holland Fifth Wheels Coupling

- Chock the front and rear of the trailer tires to prevent the trailer from moving.

- If equipped with a standard fifth wheel , check the surface of the fifth wheel for a liberal coating of grease.

- Ensure the fifth wheel jaw is fully open and the release handle is in the unlocked position.

- Make sure the fifth wheel top plate is tilted rearwards with the ramps down and resting on the tilt stops.

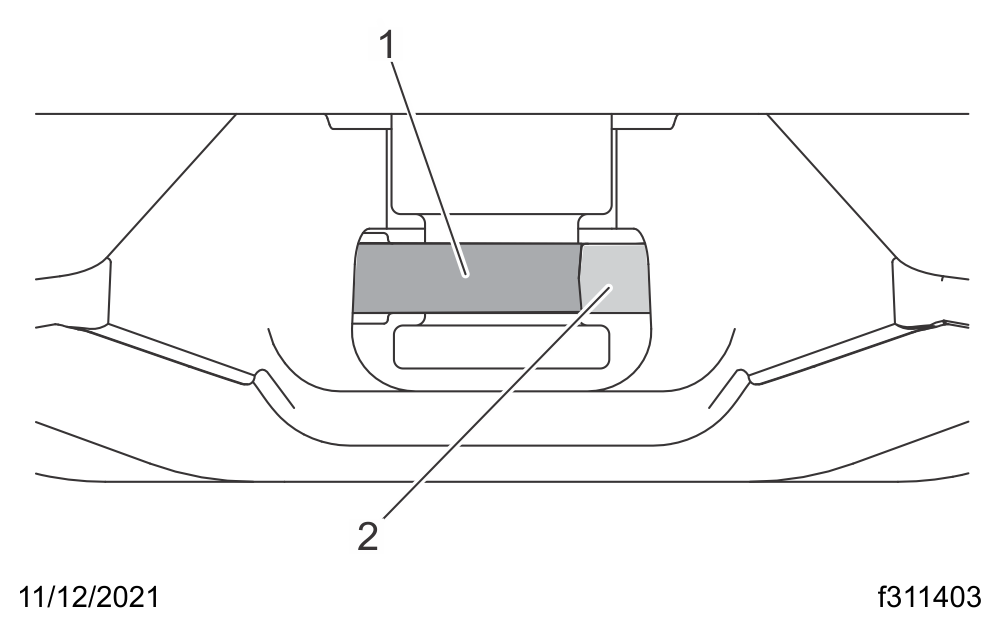

- Position the tractor so that the center of the fifth wheel is in line with the trailer kingpin as shown in The kingpin should be in a position to enter the throat of the locking mechanism.

- Adjust the trailer height if required.

For a standard fifth wheel plate , the trailer should contact the fifth wheel approximately 4 to 8 inches (10 to 20 cm) behind the fifth wheel pivot as shown in Fig..

- With the fifth wheel lock opening aligned with the trailer

kingpin, back the tractor slowly toward the trailer. After sliding

under the trailer, stop to prevent from hitting the

kingpin, then resume backing up slowly until the fifth wheel locks.On a standard fifth wheel, the fifth wheel must lift the trailer.On a no- or low-lube fifth wheel, do not lift the trailer. Lifting the trailer with a no- or low-lube fifth wheel may damage the fifth wheel plate.

- Apply the tractor parking brakes.

- Perform a coupling inspection.

- Verifying a Holland FW35/31 fifth wheel is locked:

- Verifying a Holland FWAL is locked:

- Verifying a Holland FW35/31 fifth wheel is locked:

- Release the tractor parking brakes.Test for kingpin lockup by slowly inching the tractor forward, pulling the trailer against the chocks.

- After lockup is completed, connect the tractor-to-trailer air system lines and the electrical cable to the trailer. Take care to prevent dirt or foreign material from entering the air system lines.

- Charge the air brake system with air, checking that the air connections do not leak.

- With the trailer wheels chocked and the brakes set, check for clearance between the kingpin and the fifth wheel jaws by moving the tractor forward and backward against the locked kingpin. If slack is present, uncouple the trailer and have the fifth wheel inspected and adjusted by a certified technician.

Notice: Attempting to couple at the wrong height may cause improper coupling, which could result in damage to the fifth wheel or kingpin.

Warning: A visual inspection is required by law.

Some improper couplings can pass a pull test. Sound is not reliable.

Get out of the cab and look.

Incorrect coupling could cause the trailer to disconnect, possibly resulting in serious personal injury or death.

Notice: Always make sure the connection hanger keeps the trailer air hoses and electrical cables positioned so that they do not rub on anything. Rubbing may wear through hoses or cables, resulting in air leaks, or exposed or broken wires, potentially affecting trailer brake or electrical systems.

Warning: Incorrect fifth wheel lock adjustment could cause the trailer to disconnect, possibly resulting in serious personal injury or death.